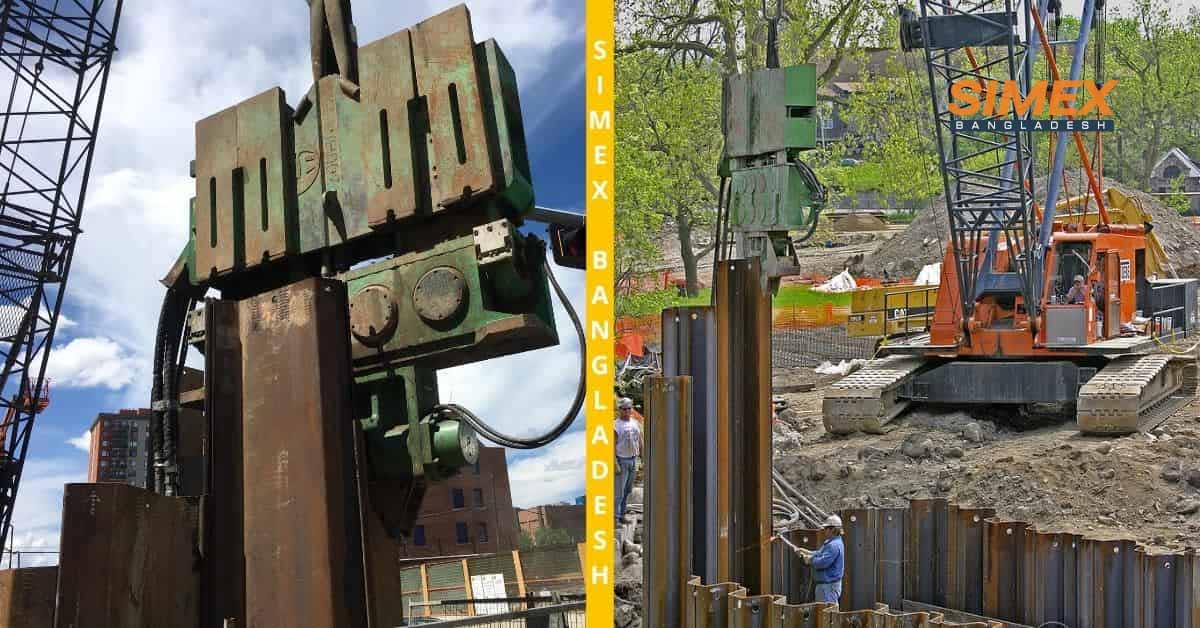

Sheet Pile Driving Installation (活頁剝離安裝) In 2022

A steel sheet pile is a structure made with steel for using in holding underground soil for making retaining wall, jetty, underground parking, etc. Steel sheet piles are making with heavy, strong, and durable steel. It contains no harmful chemicals for the soil while fitted in the soil. It is water-proof and safe from rust.

Steel sheet piles are sections of sheet materials with an interlocking border that are driven into the underground to provide earth holding and digging support. Sheet piles are also made from timber or reinforced concrete.

Sheet pile has been used to support mining for underground parking structures, basements, pump houses, and foundations, to construct tunnels, seawalls, and bulkheads. For a long service life, permanent steel sheet piles are designed. A sheet pile is highly water-resistant and a unique and durable bond offering.

Steel sheet piles are produced using the state-of-the-art facility that works under rigorous quality control. These sheet piles are available at economical design. The joints of steel sheet piles have a sufficient margin of flexibility when combined together to ensure excellent interchangeability and workability.

In Bangladesh, there are using many types of sheet piles for construction work. Some popular types of sheet pile founding in Bangladesh are as follows –

In Bangladesh, mainly U type sheet piles are using for construction projects. They are predominantly manufactured as hot-rolled section, although cold formed sheet piles are also manufactured. There are some advantages of using steel sheet pile. \

The Advantages of Steel Sheet Piles – 鋼板宮的優勢

- They are recyclable and reusable.

- It comes in a large range of lengths, sizes, and steel options.

- No requirement to excavate for wall foundations

- No disturbance of existing ground unlike that for bored concrete piling.

- Using both temporary and permanent structures.

- Easy to install when using silent and vibration-free methods.

- The work is neat, clean, and creates no spoil arising’s.

- The supervision of work on-site can be reduced, and minimal storage space is required.

- It can provide a close-fitting joint to form an effective water seal.

- They have a long life above and below water, making them advantageous for marine and coastal projects.

Sheet Piles Can be Installed in a Day

Sheet piling is lasting for many years. There is no specific sheet pile installation method for sheet piling. Everyone using their own installation method. For achieving the full performance of the structure, the sheet piling must be driven to a specific depth by the engineers.

The most famous way to install with the male lock leading; the female lock leading has a tendency to fill up with soil and hinder driving is used as the leading edge.

The most common installation method of steel sheet pile walls is including vibrating, impact driving, hydraulic pressing, jetting, and trenching. The type of sheet piling often wields the method of installation.

There are some basic installation steps for installing sheet piles. They are-

- The first step is to arrange the sheets in sections for checking if they will connect correctly or not.

- The second step is, as per the design, hammering the first sheet to the defined depth.

- The third one is for installation using vibratory hammers, but if the soil is hard or dense use impact hammers.

- Another step is if vibrations are prohibited at that particular site for installing then use hydraulics to push the sheets into place.

- After the first sheet is placed, drive the second sheet so that it interlocks with the first one.

- Then until the wall is completed repeat the process.

- And the last step for installing a sheet pile is using connector elements to maintain the integrity of the wall if it requires complex shapes.

Per Day Sheet Piling Installation-

Mainly, how many sheet pile will install a day is totally depends on the condition of the soil. There is a matter of low-tide and high-tide, the ground is solid or soft.

If there is low-tide, it is difficult to install sheet pile. In this case, only 5-10 sheet piles will be installed.

If there is high-tide, installing sheet piles are easier. It is possible to install 15-20 sheet piles when high-tide occurs.

In case of solid ground, shit pile driving is

A rate of 20 – 25 sheet pile can install per day to 20 to 35 meters deep.

1 no = 0.4 meters wide on plan and 6 meters long.

Therefore 8 – 10 meters per day per rig is achievable.

Another Measurement of Sheet Pile Installing is-

For difficult areas, such as through existing ground or a sea wall for example.

A rate of 10 – 12 sheet pile can install per day to 20 meters deep.

Therefore 4 – 6 meters per day per rig is achievable.

For more shallow sheet pile walls

Driven by – Pile master 60.0 meters per day

Driven by – Automatic Drop Hammer 32.0 meter per day

Steel for piles is usually readily available and a two-week lead-in is often all that is required.

The sheets piling installing equipment are sheet pile, soil, driving template and if required, driving assistance, noise & vibrations. If it is based on an extensive soil investigation then a piling can only be successful. Steel sheet pile installation is a quite complex process that should be stirred by experienced engineers.

The standard sheet pile installation techniques are successful with using-

- Vibratory hammers

- Impact hammers

- Hydraulic presses

When installing a sheet pile engineers have to keep in mind some caution. Taking all the precautions engineers should install the sheet pile. There are some important caution for sheet piling driving-

Caution for Sheet Piling Driving – 薄板掛架驅動的原因

- Always established a template system.

- When driving long, heavy sections of steel sheet piling, crane boom length should be twice that of the sheets one is driving.

- A panel of sheet piling should be threaded and set prior to driving any sheets to grade

- Align and plumb the first two sheets and drive carefully and accurately.

- Drive sheets in pairs when possible placing the hammer in the center of the pair.

- Some contractors recommend not driving a sheet more than 1/3 its length before driving the adjacent pile.

- Never rush the Pile Foreman.

Contact Us

Contact with your trusted Sheet Piles Supplier in Bangladesh or inquire about what we can do for you. We have dedicated customer service representatives who can answer all of your questions. We’re always happy to provide you with our services and information over the phone or schedule a time to discuss your project face to face.

———-

Sales: +8801733331033

Engineering: +8801733331032

销售老板: +8801733331031

Mail Us:

Head of Sales: shuvo@simex.com.bd

Head of Engineering: jamil@simex.com.bd