Bridge, structure that ranges on a horizontally between supports, whose capacity is to convey vertical loads. The prototypical bridge is very straightforward—two backings holding up a beam—yet the designing issues that should be overcome even in this basic structure are inherent in every bridge: the supports should be sufficiently able to hold the construction up, and the range between supports should be sufficiently able to convey the loads. Ranges or spans are generally made as short as possible; long spans are defended where acceptable establishments are restricted—for instance, over estuaries with profound and deep water.

All significant and major bridges are constructed with the public’s money. In this manner, bridge design that best serves the public interest has a triple objective: to be as effective, as conservative, and as rich as is safely possible. Productivity is a logical rule that puts worth on diminishing materials while expanding execution. The economy is a social rule that puts value on lessening the expenses of construction and maintenance while holding effectiveness.

Finally, elegance is a representative or visual principle that puts value on the individual articulation of the designer without trading off execution or economy. There is little conflict over what comprises proficiency and economy, yet the meaning of a class has consistently been questionable.

Main Parts of a Bridge Construction

Let’s look at the main parts of a bridge in more detail and consider the components that make up the three core areas:

Piles: Piles are normally laid to give support to a bridge and make up the underlying foundation. The piles help the weight and stress applied by the bridge to be communicated equitably through the ground making it steady and solid.

The material and design of a pile rely upon a few factors, for example, soil type, ground fragility, and burden-bearing limit requirement. For bridges on rivers, scouring is additionally considered before the bridge is designed.

Caps: Caps give extra load moving ability to the piles. They are otherwise called pile caps as they are put directly on top of the heap establishment. Caps are frequently made of weighty cement to invigorate most extreme the upper piece of the bridge.

Bents: When piles and caps are set together they are called bents. Numerous bents structure the establishment for the base.

Abutments: Bridges have vertical supports at their moving toward grounds, working as maintenance walls for the ground. These are worked from supported cement and are equipped for withstanding significant levels of horizontal force.

Piers: When there are multiples spans in a bridge, then, at that point wharves are mounted toward the end of each to give sustenance from powers and vibrational impacts, going about as supporting focuses for the bridge.

Pier Caps: Pier caps are also called the headstock. This capacity is space for braces to move loads on the course (that split the pile between every one of the wharves), from the superstructure parts on the top.

Girders: Girders join all the pile caps together by reaching out over them. Braces are additionally alluded to as pillars and offer help to the deck. This can be a single span, or even different spans joining every one of the bents, subject to the length of the bridge. Girders typically have a truss design to improve pressure and load resistibility. Subsequently, pressure is immediately passed towards the foundation. Girders are for the most part produced using metal or cement.

Bearings: Bearings provide allowance between these parts. Bearings are underlying individuals equipped for moving loads from the deck to the base. These dislodge stresses and load the docks through the braces to permit construction between parts of a bridge. The movement can be straight just as torsional. Heading gives recompense between these parts.

Trusses: Trusses are made by joining three-sided segments to isolate loads and bending moments through the bridge. A few kinds are simple trusses, suspension, and furthermore cantilever supports. The truss network gives a surface to transportation which can be worked as deck support, horse bracket, or through support. Each support contrasts in how the rush hour gridlock will continue forward the bridge.

Decks: Decks get the immediate traffic load. Some essential decks can be made of cement and furthermore from metal. These incorporate travel or strolling ways, seepage frameworks, checks, development segments, walkways, and approach pieces.

Barriers: Mainly as security and assurance include, spans have hindrances on the sides of their decks. These can be uncommonly planned installations, ropes, rails, fences, or substantial dividers for a better feel.

Arches: A bridge with arches has a ton of strength. Arches can help control the security and load-bearing capacity of the bridge. The amount of curves and materials used for construction is vital. A space interfacing the bridge columns and deck shaft are known as the spandrel. There can be open or shut spandrels relying upon the arch design.

Bridges play a crucial role in transportation. As such, multifaceted calculations and in-depth feasibility analysis are carried out before the design for a bridge is finalized. Aspects like the environment, load capacity, soil type and preservation, material, construction methodologies and techniques all need be taken into consideration when planning a bridge.

Materials Used for Bridge Construction

Some of the main materials found on construction of a bridge are steel, concrete, stone and asphalt. Other materials include iron, timber, aluminum, rubber and other joint materials. Below is a description of some typical uses for these materials in a bridge construction.

Concrete

Concrete is usually used for some bridge superstructure individuals like decks, pre-focused on cement footers, checks, walkways, and railings (side traffic hindrance dividers). It is used broadly in new construction for the whole projection, including the footings, stem (fundamental front divider), wing dividers, cheek dividers, back dividers, end dividers (for traffic obstruction association), bar seats, and the wharfs with comparable members. It can also be used for cast set up or precast substantial heaps to help the abutments and piers.

Steel

Steel is regularly used in the bridge superstructure for protecting expansion joints, bars, heading, and floor radiates, supports, building up bars in concrete, traffic obstructions and brackets. It is used in the foundation for the building up bars in concrete, reinforcing for extension joints, anchor bolts, and so on. It is also used for piles to support the abutments and piers.

Stone

Stone was regularly used for building projections and docks during the 1940s and prior. This is especially obvious where neighborhood fieldstone was promptly accessible.

Asphalt

Asphalt is the material that has been used widely for the wearing surfaces on folded metal decks, lumber decks, and substantial decks in bridge construction.

Iron

Iron was used commonly in pillars and trusses that were worked before 1900 for construction of a bridge. Steel supplanted iron since it has more rigidity than iron and is less weak. There are basically no uses for iron in the present bridge design.

Timber

Timber or wood is used for a few decks and traffic boundaries in Bangladesh. It is also used for the pillars on one extension and the projections and piles on another bridge.

Types of Bridges

There are 7 main types of bridges: Arch Bridge, Beam Bridge, Cable-stayed Bridge, Cantilever Bridge, Suspension Bridge, Truss Bridge, and Tied Arch Bridge. The way in which the vertical/horizontal stresses are managed dictates the structure of different bridges. In some cases the deck area will be the load-bearing element while in others it will be the towers. There are also designs that transmit tension through bridge cables which allow a degree of flexibility for different terrains.

Arch Bridges

There are various types of curve bridge yet they all share focal components for all intents and purpose. Each bridge has abutments, which are used to help the bended arch structure under the bridge. The most widely recognized sort of arch Bridge is a viaduct, a long bridge made of numerous arches.

The sidelong pressing factor made by the arch span is moved into the supporting projections. It is in this way fundamental that these pieces of the scaffold stay strong, flawless and very much established.

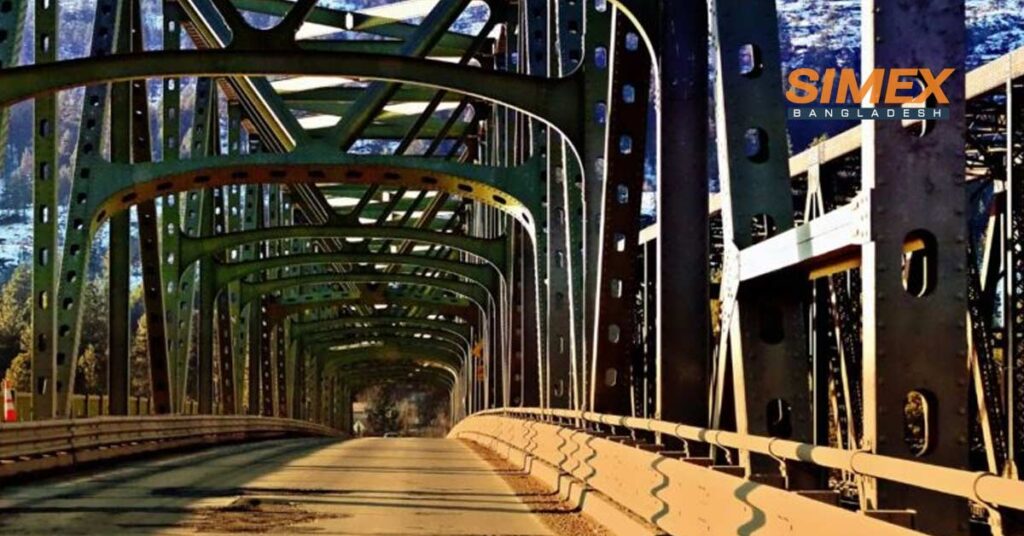

Truss bridges

The truss bridge has been around for in a real sense hundreds of years and is a load-bearing construction which fuses a support in a profoundly proficient yet basic plan. You will see a variety of several varieties of the basic support bridge yet they all fuse three-sided areas. The part of these three-sided components is significant in light of the fact that they viably assimilate pressure and pressure to make a focused on structure ready to oblige dynamic burdens. This combination of pressure and pressure guarantees the design of the bridge is kept up and the decking area remains positive even in generally strong winds.

Cantilever bridges

At the point when the primary cantilever bridge was designed it was viewed as a significant engineering breakthrough. The bridge works by using cantilevers which might be straightforward pillars or supports.

They are produced using pre-focused on concrete or underlying steel when used to oblige traffic. At the point when you consider that the even bars making up the cantilever arm are just upheld from one side it starts to sound somewhat risky.

Beam Bridges

A beam bridge is probably the simplest kind of bridge. An ideal example being an essential log bridge – something you may see while out on a nation walk.

The deck region generally comprises of wood board or stone slabs (regularly alluded to as a clapper bridge). These are supported either side by two beams running between projections/piers.

Suspension Bridges

The construction of a stereotypical suspension bridge looks basic however the plan is very viable. The deck of the suspension bridge is the load-bearing component of the design. This is held set up by vertical suspenders which support the cables. The suspension cables extend out past each side of the bridge and are secured immovably into the ground.

Tied Arch Bridges

The tied arch bridge is an intriguing design which fuses a curve structure (generally metal) supported by vertical ties between the arch and the deck. The tips of the arch structure are associated by a bottom chord. This demonstrates also to the line of a bow. The descending pressing factor from the arch design to the deck of the bridge is converted into strain by the upward ties. Numerous individuals expect that the projections guarantee that the tied arch bridge and arch structure stay in space.

Cable-Stayed bridges

A cable stayed bridge is dependent upon towers/pylons which are the load-bearing element of the structure. Cables are bridged from the pylons to the deck below. This is the feature many people associate with cable stayed bridges. This type of structure tends to be used for distances greater than those achieved with a cantilever bridge design but less than a suspension bridge.

Different Methods of Bridge Construction

Described below are the different methods in the construction of bridges.

This method is an adaptable and flexible method for bridge construction where complex and uncommon mathematical states of dams can be built without any problem. In circumstances when it is difficult to transport prefabricated components either because of size or inaccessibility, this method is a decent choice. Bridge Construction Company will help you to construct a bridge applying this method.

This method is used for constructing bridges range 50 to 250m. The bridge constructed can either be cast-in-place or precast. Here, the portions are attached in an elective way at far edges of the cantilevers supported by piers. This is the most ideal decision for the construction of long-span length bridges, sporadic length, and cable-stayed bridges.

In this method, the bridge is constructed with the assistance of precast substantial components. The construction is acted in various methods. The precast components include:

A. Precast Beams

B. Precast Decks

C. Precast Segmental Decks

This method is related with the cantilever construction strategy however with much progression in the procedure, it is considered as generally monetary and fast in construction. For long bridges and viaducts with an individual span up to 60m, the strategy is feasible. Decks are started at one abutment and constructed persistently by putting sections to the opposite end of the bridge. Sections can be situated by either a transitory remaining pole framework through more generally using a get together support.

The Incremental Launching Method (ILM) method for bridge construction is used predominantly for the construction of constant substantial bridges or steel support spans. The method performs the procedure in increments. With this method of construction, the bridge deck is underlying areas by pushing the design outwards from a projection towards the pier. The ILM method can be used for bridge decks with a length more noteworthy than 250m.

In the cable-stayed method of construction, cables are used to convey the bridge deck from one or the two sides of the supporting tower. The cables convey and move every one of the loads to the foundations. Cable-stayed method of construction is used for constructing bridges that span more than 300m.

Arch shaped bridge construction is quite possibly the most conservative decisions when the bridge under consideration is needed to get over scenes that are distant. Many modern arch construction methods have made arch construction more efficient. The arch construction can be worked with concrete or pre-cast concrete. The cast-in-situ free cantilever methods and slip-framed areas are two primary construction procedures going under arch methods.

Factors Affecting Selection of Bridge Construction Methods

Before a bridge can be built an appropriate method of construction must be chosen. The decision is made by the design team. The principle factors considered by the design team when choosing a suitable method of construction are given below:

- The scale of the bridge

- The obstacles to be crossed

- The regularity of the span lengths

- The horizontal and vertical profiles of the bridge decks

- The nature of the soil strata

- The local weather

- The local cost of materials

- The local labor markets

- The accessibility of the site

- The time allowed for construction.

Our Bridge Construction Services

Over the years, SIMEX Bangladesh has built some of the country’s most notable bridges. We pride ourselves on our ability to utilize in-house engineering to develop the tools, equipment, and methods for the timely and safe construction of bridge structures throughout the country. Let’s check out some bridges we constructed various time periods.

Cable-stayed Bridges

From foundations to tower tops, and every part in between, SIMEX Bangladesh has excelled at the construction of cable-stayed bridges since our earliest days. We are experienced with foundations; towers and piers; stay-cable fabrication, erection and tensioning; suspension cable erection, superstructure erection, structural health monitoring system installation, and maintenance and repair. Maintaining global relationships with suppliers of fabricated structural steel is core to our business. We use leading technology for the engineering and erection of main cables, suspender cables, deck segments, load transfers, and compaction and wrapping of main cables.

Moveable

We have constructed all types of movable bridges and other moving structures, including vertical lift, bascule, and swing spans. We self-perform mechanical equipment installation, calibration, and commissioning in addition to foundations, piers and structural construction. Our experience covers truss float-in methods, bascule girder erection, counterweight jacking systems, counterweight suspension system installation and replacement, primary and secondary reducer procurement.

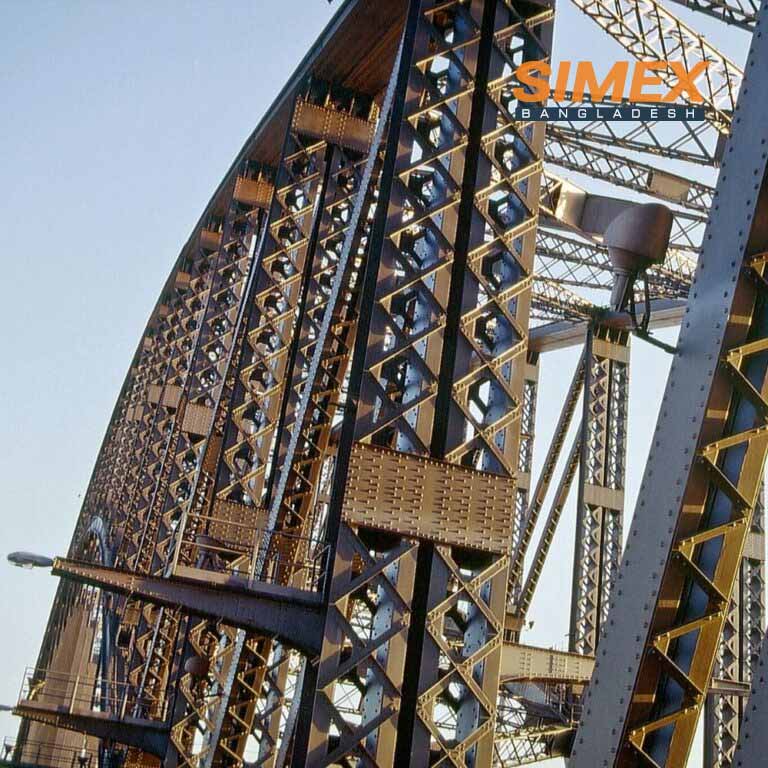

Arch Bridge

SIMEX Bangladesh has constructed both true and tied arch bridges using aerial cableways, tieback, and float-in, false work, and jacking technologies. Over the course of our history, we’ve constructed more than 15arch bridges, serving pedestrians, automobiles, and railroads.

Truss Bridge

We have experience with truss erection by balance cantilever, single pick, float-in, tie-back, launch and slide-in – using water based cranes, and land based cranes, traveling gantries and jacks. We also construct and maintain truss bridge foundations, piers, abutments and decks.

Why Choose Us as the Best Bridge Construction Company in Bangladesh

SIMEX Bangladesh is leading and largest family-owned bridge Construction Company in Bangladesh with unparalleled self-perform experience and resources to serve the transportation sector constructing iconic bridges in Bangladesh. We are the preferred contractors for bridge construction. We are having vast experience in the field of bridge construction. We have completed several projects of bridge in past and we are also running with the new bridge projects all over the country.

Safety in all we do and build is fundamental to prosperity for our customers and our employee-owners.

Established in 2005, SIMEX Bangladesh is leading bridge Construction Company in the country. Our expertise spans multiple markets, including transportation, industrial, building, concrete and renewables.

There are many ways to control quality, and one of the best is to do the work yourself.

At SIMEX Bangladesh, innovation isn’t just a word we write into proposals. It’s a value hardwired in the way we work.

We build prosperity by sharing our own. Giving back and responsible stewardship are core parts of our culture.

Our Working Process

For Bridge construction, SIMEX Bangladesh has more than 12 years of construction knowledge within river works, drainage, utilities and the civil engineering sectors. Through our uplifting perspective on plans and our goal-oriented thoughts, we have built a reputation which we will continue to build on. We are committed to delivering to our clients a professional and no fuss service. We are pleased with the information and experience we have acquired and we are fully focused on being a market leader in the many years to come.

When our clients choose us for constructing a bridge. We first arrange a meeting with them and hear about their plan about constructing the bridge. After hearing from them, we discus with them what we can do or cannot do with their planning.

After the meeting and planning about the bridge construction, we along with our clients go to the construction site for seeing the place where the bridge will be construct. Visiting a real time construction project allows to develop a greater understanding of the bridge construction. Based on the location and the condition of the waterways and soil of the areas, the bridge design will be edited and developed.

The initial phase in any bridge construction is appropriate planning and evaluating the necessities which is proposed to serve. Local soil condition both current and future ought to be contemplated, and a cost-effective analysis should be performed by private organizations to ensure they will actually receive good value for their investment in construction.

The execution phase turns the construction plan into action. Our expert engineering team carries out all the planned activities, constructs deliverables, and presents them to project stakeholders. Effective communication plays a huge role during execution of the bridge construction. We ensure that the budget stipulated in the planning stage that should be followed strictly.

Over time, waterway and environmental effects will damage bridge piles and other part of the bridge which require rehabilitation. Life expectation of bridge construction and maintenance projects varies from country to country, but we always tries to monitoring the projects after successfully delivered that to our clients.

Trusted Bridge Construction Company in Bangladesh

Make A Safe Deal With SIMEX Bangladesh

Faruk Khan

SIMEX Bangladesh was completely respectful of the bridge construction - they immediately became part of our team and they know teamwork! Working with SIMEX Bangladesh is nothing short of a first class experience!

Yaqub Nipu

We have worked with SIMEX Bangladesh team in the past and once again they exceeded our expectations. There were some Covid-related delays, but the team was very transparent about the bridge construction project delivery challenges at the onset, and updated us regularly. So, undoubtedly it is best bridge Construction Company in Bangladesh.

Alex Neon

Workers were friendly and efficient. They completed the temporary bridge project on time. I am delighted with their work. SIMEX Bangladesh team was always punctual for their responsibilities. I cherished for constructing more bridge from them. They are the best temporary bridge construction company in Bangladesh.

Jubayer Ahmed

Thank you SIMEX Bangladesh! I sincerely appreciate all of your hard work and expertise. You completed my new bridge project on time, and helped make this whole experience great from start to finish, and then some. You are truly master technical, and your work is outstanding. The team is dependable, honest, timely, trustworthy, and knowledgeable. You will always be my first choice in construction. I will highly recommend you as the best bridge construction company in Bangladesh without hesitation.

Mukul Hossain

SIMEX Bangladesh has been an incredible partner and we have a great deal of trust in them to be able to meet our accelerated goals with bridge construction project. We are 100% satisfied with the leading bridge construction company in Bangladesh. They are really trust worthy.

MD Lutfur Rahman

We found a best temporary bridge construction Company for a long time. Then we found SIMEX Bangladesh. After one meeting we hand over our project to them. The whole team was very efficient, responsible and completed the project before deadline. We are fully satisfied what they do for us. After completed the project, they always follow-up the project as their own. I would highly recommended SIMEX Bangladesh as they are best temporary bridge Construction Company in Bangladesh.

Tushar Ahmed

We were impressed by the flexibility and level of professionalism shown by SIMEX Bangladesh during this complex phase of bridge construction. As the project reached completion, the team went above and beyond to provide excellent customer service to ensure that our team had all of the resources we needed for the bridge. So we believe that SIMEX Bangladesh is now well doing bridge Construction Company in Bangladesh.

Shrneon Chowdhury

I want to thank the SIMEX Bangladesh team for your successful completion of the bridge. The whole team was first class to work with and impressed us with their attention to detail, positive customer service, and managing to a tough schedule. I would look forward to the opportunity to work with the leading bridge construction company in Bangladesh again on a future project.

Hossain Ali

SIMEX Bangladesh is one of the best bridge construction companies in Bangladesh we've worked with. The entire team tactfully delivered a project of exceptional quality while staying on schedule and under budget. We hope to work with this company again in the near future!

Liton Gazi

SIMEX Bangladesh team was great to work with – courteous and professional. Promptly showed up as scheduled. Very well coordinated group, clean and efficient who completed the project on time. As it is now a renowned bridge construction company in Bangladesh, I would recommend it undoubtedly.

Faruk Khan

SIMEX Bangladesh was completely respectful of the bridge construction - they immediately became part of our team and they know teamwork! Working with SIMEX Bangladesh is nothing short of a first class experience!

Yaqub Nipu

We have worked with SIMEX Bangladesh team in the past and once again they exceeded our expectations. There were some Covid-related delays, but the team was very transparent about the bridge construction project delivery challenges at the onset, and updated us regularly. So, undoubtedly it is best bridge Construction Company in Bangladesh.

Contact Us

Head of Sales

Phone/ WhatsApp/WeChat: +8801733331033

E-Mail: shuvo@simex.com.bd

Head of Engineering:

Phone/ WhatsApp/WeChat: +8801733331032

E-Mail: jamil@simex.com.bd